Let’s be honest, the word “poop” typically brings up some pretty unpleasant images. Yet, one pioneering company in Sri Lanka has taken an unexpected natural resource — elephant dung — and turned something we normally consider waste into paper, which is surprisingly functional and an award-winning example of sustainability. At first, it may sound unusual, but once you understand the science, it’s nothing short of genius.

Meet Ecomaximus, the social enterprise that has been transforming elephant waste into handmade eco-friendly paper since 1997.

From Dung Heap to Desktop

Ecomaximus uses elephant dung to make up to 75% of the content for their unique paper products.

How does this work?

It all comes down to the elephant’s vegetarian diet. An adult elephant eats over 200 kg of grass, tree bark, and leaves every single day. Here’s the key: their digestive systems are surprisingly inefficient.

This means a massive volume of plant material—specifically, the tough, structural fibers known as cellulose (the exact stuff needed for paper)—passes right through the animal, pre-processed and ready for collection.

Ecomaximus realized they didn’t need to cut down forests; they just needed to collect the waste of the world’s largest vegetarians.

Three Wins for Sustainability:

- No Trees Harmed: Zero dependence on wood pulp stops local deforestation.

- Waste to Value: A messy environmental problem is turned into a beautiful, sellable product.

- Conservation Incentive: The business creates a powerful economic reason for local communities to value and protect wild elephant herds.

Safe, Clean, and Sustainable

We have to address the elephant in the room: Is it gross? Absolutely not. The manufacturing process is incredibly meticulous, ensuring the final paper is totally safe, toxin-free, and odorless.

- Collection & Cleaning: After the dung is collected, it is thoroughly washed and sterilized to get rid of any contaminants.

- Pulping: The remaining clean cellulose fiber is pulped and blended, and then reformed into sheets, just like traditional papermaking.

- Chemical-Free Finish: Crucially, the final sheets are dried and finished without acids or harmful chemicals common in conventional paper manufacturing.

How the Texture and Color are Naturally Formed

The paper’s feel and appearance depend on the elephant’s diet:

- More fibrous, leafy food → rougher texture

- Better digestion → smoother paper

- Different plants eaten → natural variation in shade

This means every batch has its own character — a truly handmade material.

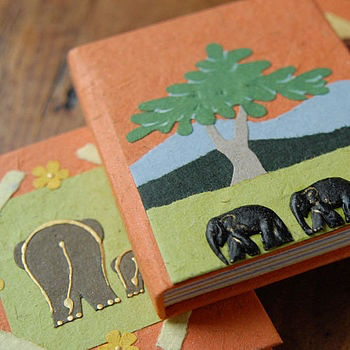

Today, Ecomaximus produces vibrant and artistic goods—from notebooks and greeting cards to decorative items that are perfect for eco-conscious consumers:

Social and Environmental Impact

Their most significant contribution, however, is their social and environmental impact. In Sri Lanka, human-elephant conflict is a real challenge. By turning elephant waste into profit, Ecomaximus:

- Supports local jobs with fair wages.

- Creates community buy-in for elephant conservation.

- Promotes sustainable rural industries that respect the local ecosystem.

A Note for Our Tomorrow

In a world drowning in pollution and facing widespread deforestation, Ecomaximus proves that the biggest solutions can come from simply looking at nature’s cycle differently. Solutions don’t always need high-tech breakthroughs.

Sometimes, the raw material for a healthier future is literally what we’re throwing away.